A La Carte Services:

Initial Consultation…50.00 per 30 minutes

Pattern making…90 per hr

Sample making…75 per hr

Raw Materials Sourcing…75.00 per hour

Production Costing Analysis…40.00 Flat Rate Fee

Development Timeline…2-4 weeks

DESIGN

To begin developing a sewn good or garment, you need to start with a design. We can work with flat sketches, pictures, or an already existing item to use as reference. But perhaps you have none of the above, only the idea. We can help you get to that point.

PATTERNMAKING

We make all of our patterns and/or provide any necessary revisions in house. We can facilitate grading of sizes and production markers as well.

FABRIC SOURCING

If you have not yet sourced materials or are looking to find a consistent supplier, we can help.

TECH PACKS

With your pattern you will need to provide the blueprints of your product. Tech packs provide to the maker the materials bill, sewing construction, finishing techniques, measurement specs and tolerances.

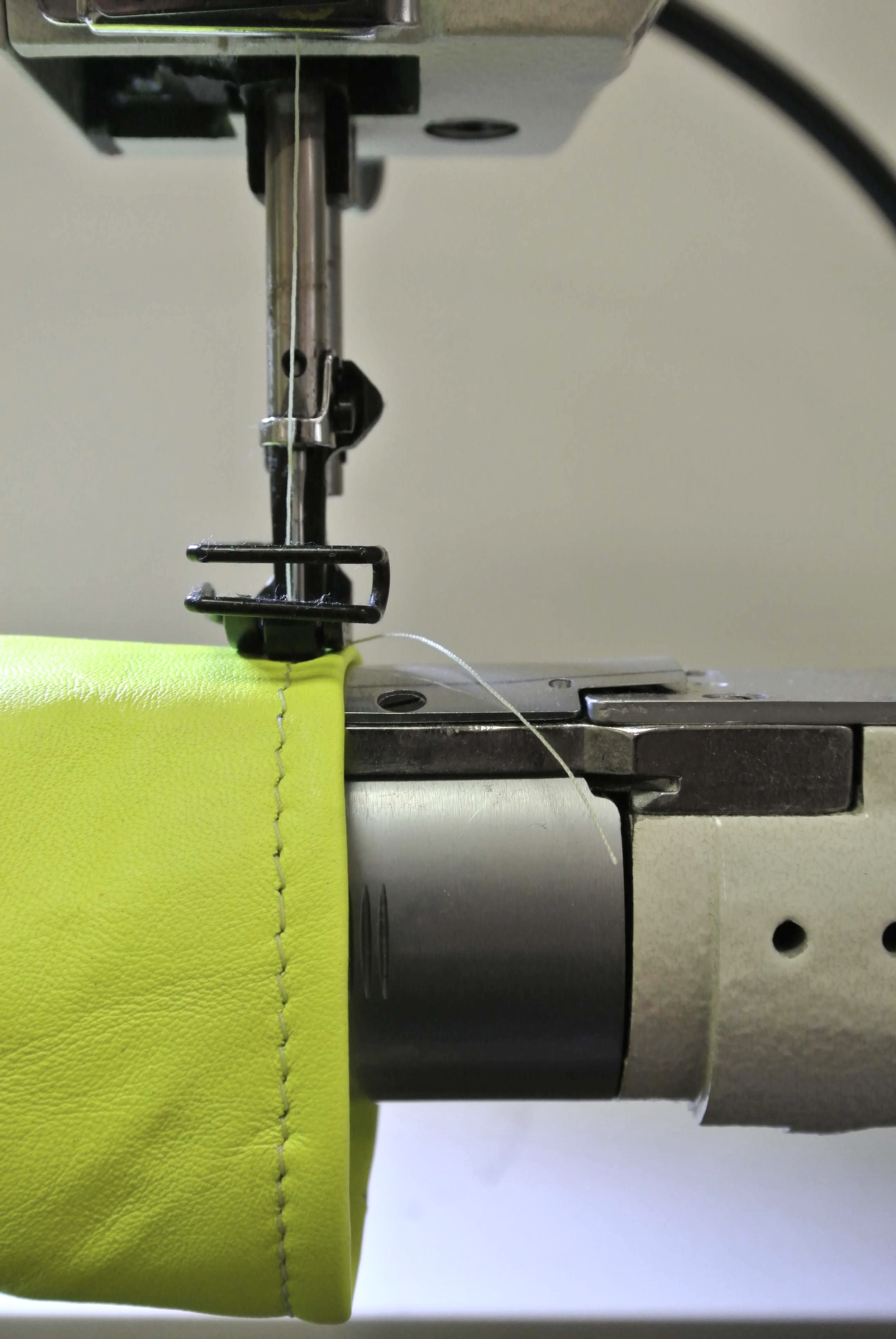

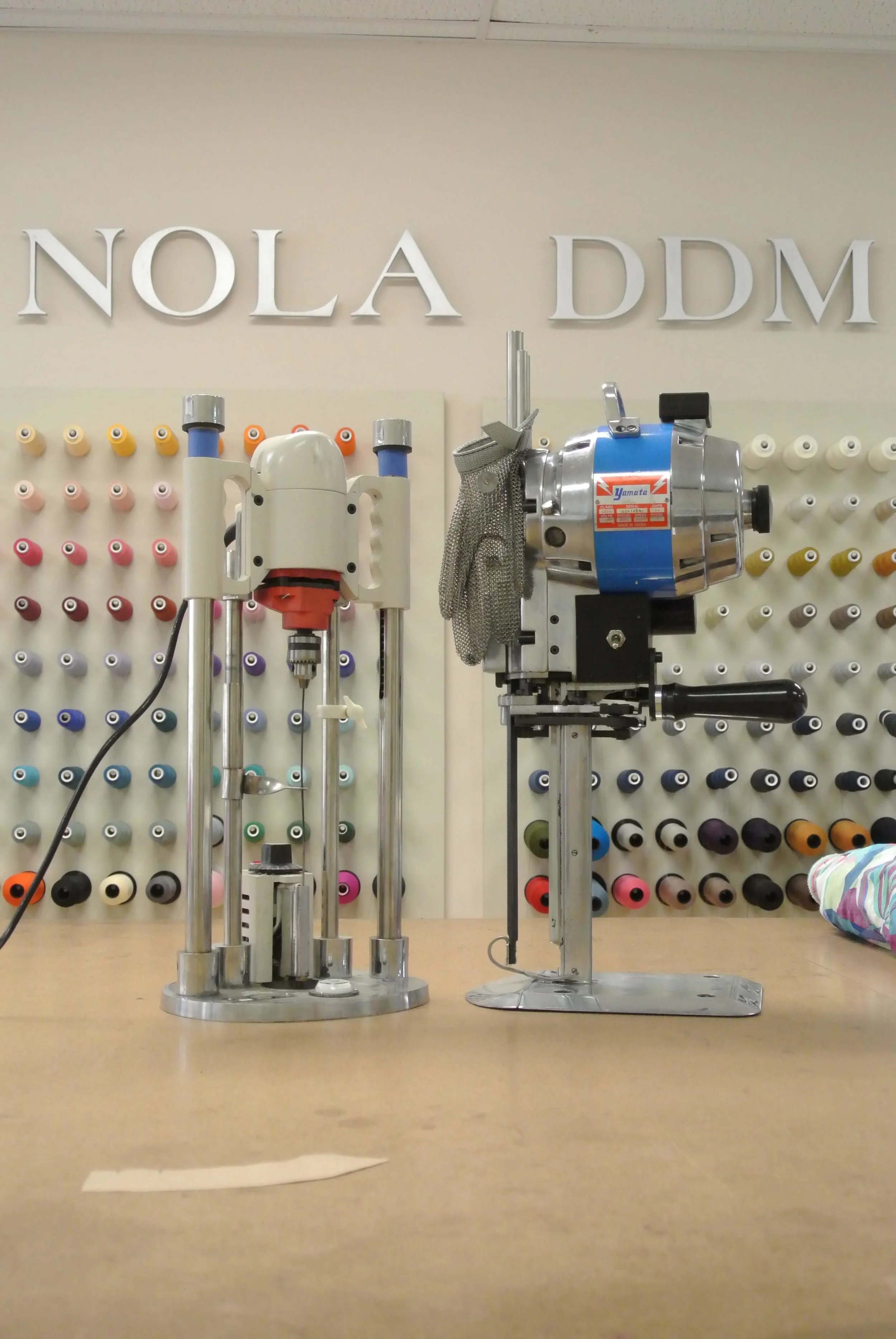

SAMPLE MAKING

Our sample room is fully equipped, and we can provide most sewing techniques and finishes. As we build your sample, we can advise you on fabric choices, construction techniques, fabric usage and any technical input to make your sewn good or garment streamlined for production.

*(prototype, muslin, fit, first, sew-by, sales, etc.)

PREPARE FOR MANUFACTURING

Once your product is sampled and approved by you in its final revisions, it can then be costed for production. Production estimates will include the labor for the cut, make, and trim involved. Based on the number of units you provide as well as your products fabric yield, you will be provided with a minimum yardage calculation necessary for production.

As with every other service we provide, we aim to make the production process as smooth as possible. We can provide you with a punch list to keep you organized from start to finish, as well as schedule an intake and inventory meeting. Once production has started you cannot make changes to your order, so it is imperative to be fully prepared with all materials in-hands before we can begin.